Production Process

-

Seat Producition Process

-

Ball Production Process

-

Body Production Process

-

Bonnet Production Process

-

Stem Production Process

Seat production processing

In order to achieve good product quality,every step of production goes through strict procedures.Take ball valve seat for example,The production process is as follows:

- Roughing Machining

- Heat treatment

- Finishing Machining

- Drilling

- Pressure seal ring

- Polishing

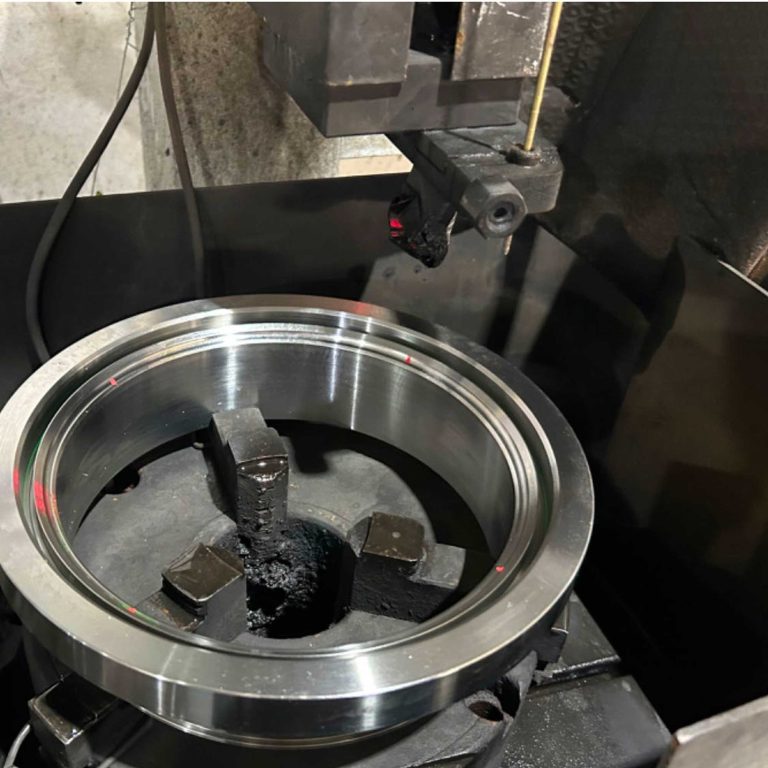

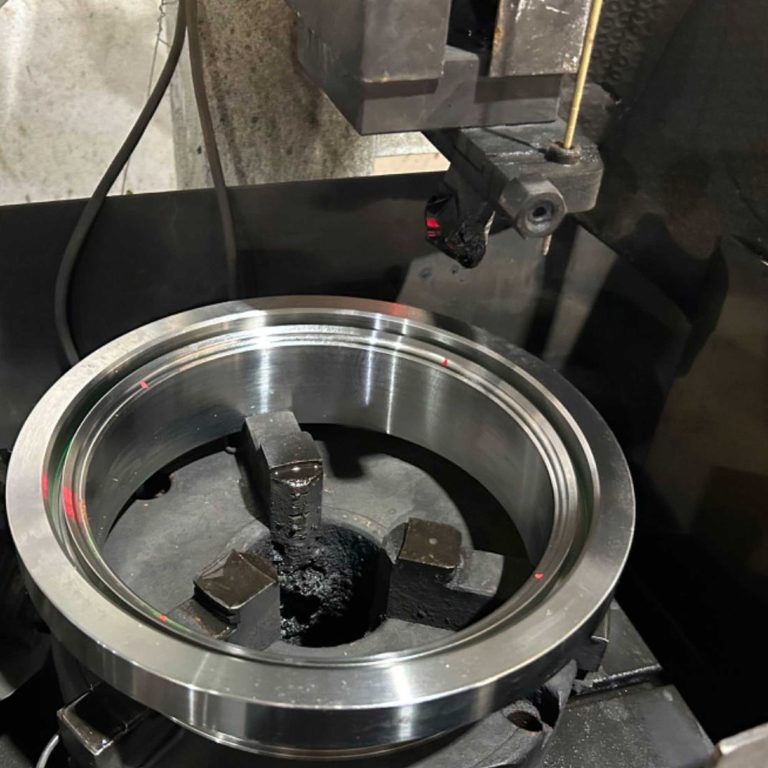

1.Roughing Machining

In the Rough machining production process,we could detect some situations timely,such as the defects in blank material,or material margin is in sufficient and so on.Then it is convenient for us to repair or scrap raw materials in a timely manner;

2.Heat treatment

In the heating processing,it could improve the mechanical properties of materials,such as hardness, tensile strength, seismic resistance, ductility, and corrosion resistance.And the heating processing consists of three stages:

- heat the material slowly;

- The material is maintained at a specific temperature for a specified period of time;

- Cool the material at room temperature.

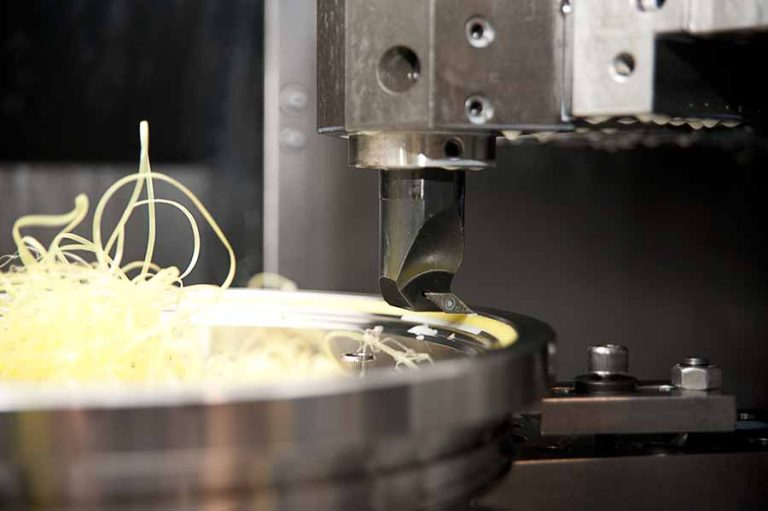

3.Fihishing Machining

In the precision machining process,the product will be processed strictly according to the dimensions on the drawing within the allowable tolerance range ,and it will become smoother than before.

4.Drilling

According to the design requirements of the product, we will drill holes for the valve seat:Spring hole, threaded hole, grease injection hole and so on,different holes will be made by different drilling tools.

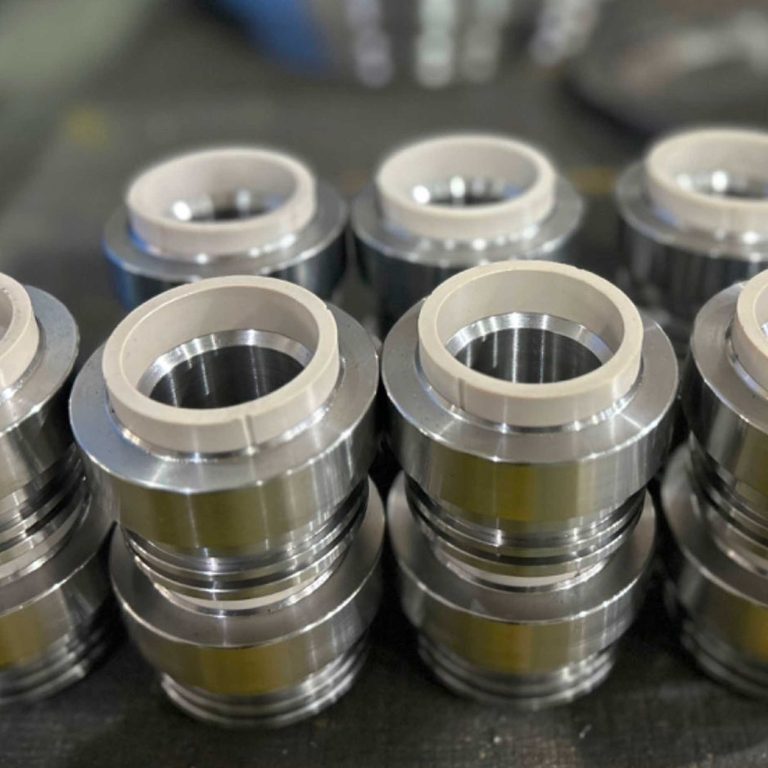

5.Pressure seal ring

We use a dedicated embedding press to embed the valve seat as symmetrically as possible into the valve seat,the valve seat provides initial preload force through its own elasticity.Sealing materials generally include:RPTFE、PEEK、PEFE and so on.

6.Polishing

ball production processing

- Raw material confirmation

- Roughing inner hole and outer circle

- Heating treatment

- Spray coating

- Chamfering

- Finishing machining

- Milling groove

- Grinding

1.Raw material confirmation

Raw material

raw matertial

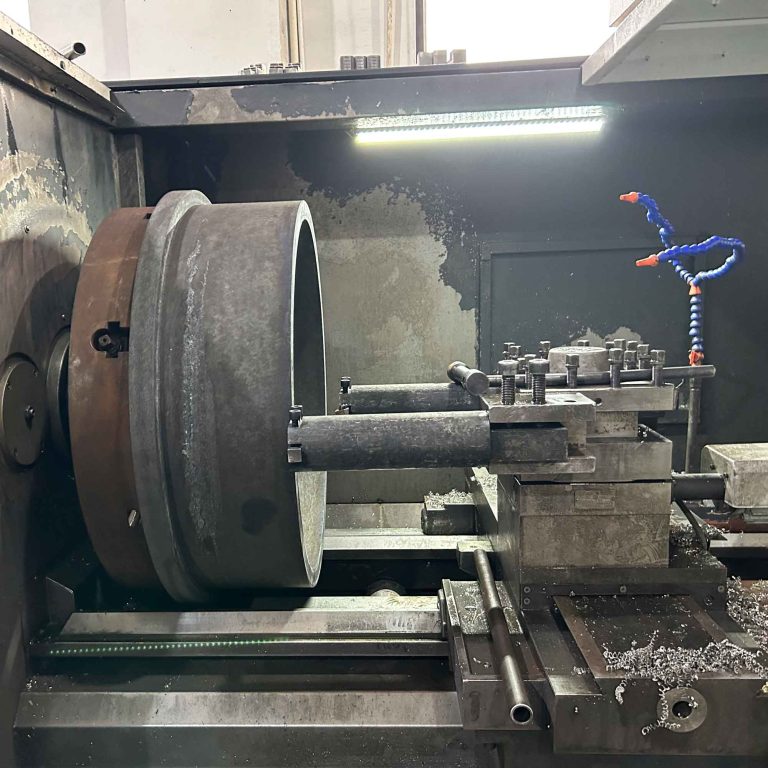

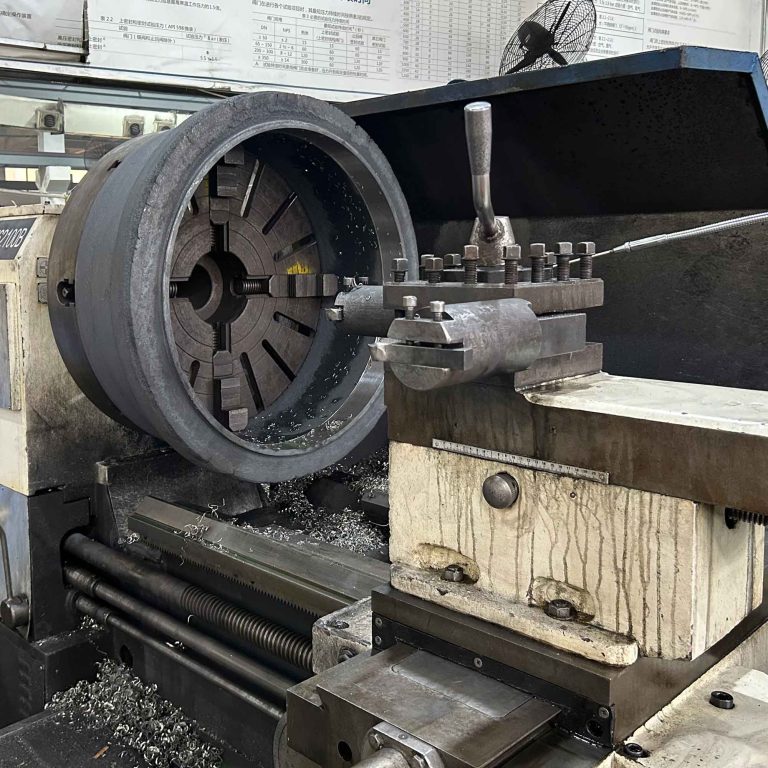

2.Roughing inner hole and outer circle

Roughing machine(1)

Roughting machine(2)

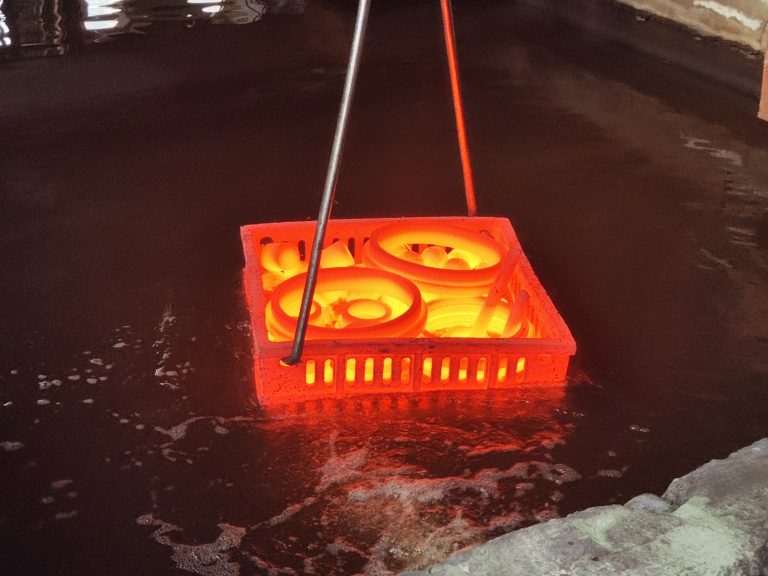

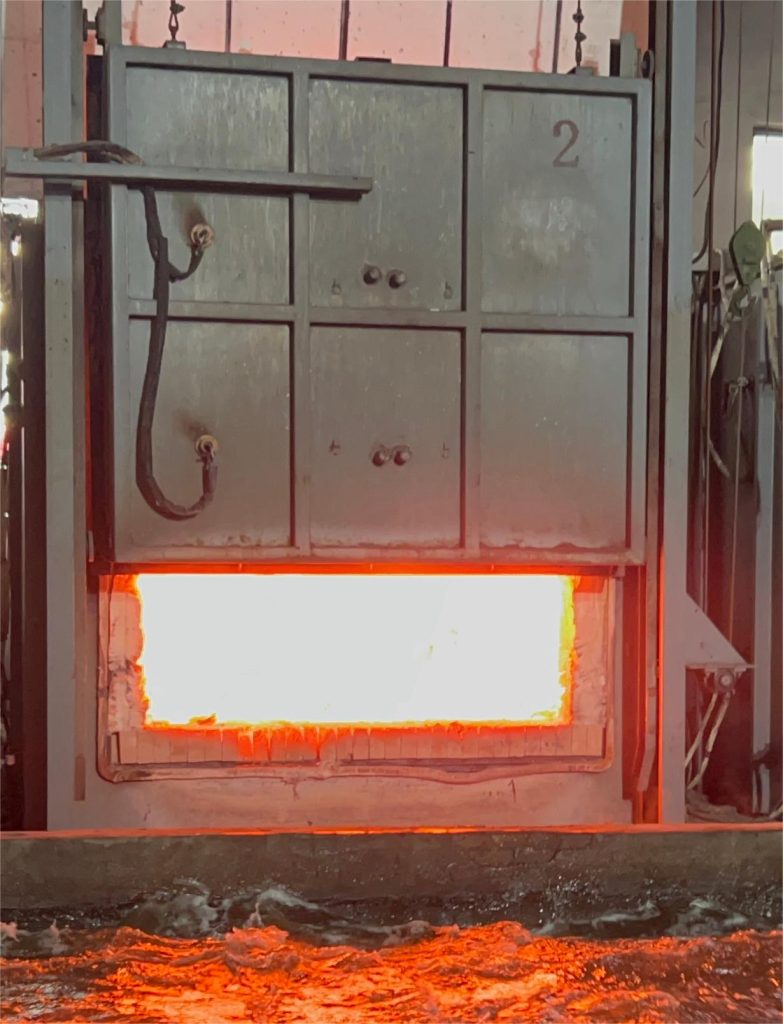

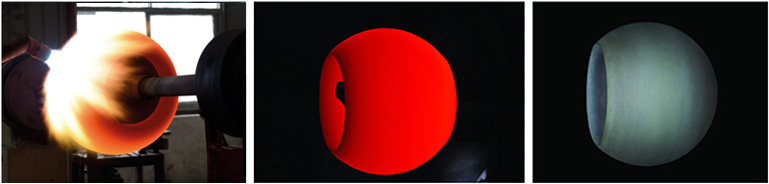

3.Heating treatment

Heating(1)

Heating(2)

Heating(3)

Heating(4)

4.Spray coating

Spray coating

5.Chamfering

Chamfering

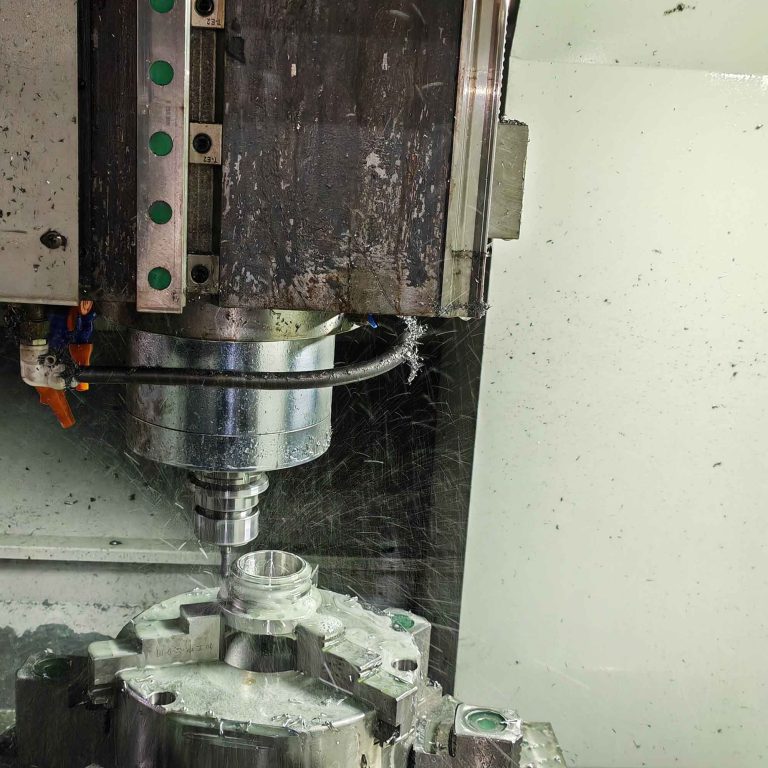

6.Finishing machining

Finishing machine

Finishing machine

7.Milling groove

Milling groove

Milling groove

8.Grinding

Grinding

9.Other balls

Metal surface coating

Metal surface coating

production processing

In order to achieve good product quality,every step of production goes through strict procedures.Take ball valve seat for example,The production process is as follows:

- Roughing Machining

- Heat Treatment

- Finishing Machining

- Drilling

- Pressure seal ring

- Polishing

4.Drilling

According to the design requirements of the product, we will drill holes for the valve seat:Spring hole, threaded hole, grease injection hole and so on,different holes will be made by different drilling tools.

production processing

In order to achieve good product quality,every step of production goes through strict procedures.Take ball valve seat for example,The production process is as follows:

- Roughing Machining

- Heat treatment

- Finishing Machining

- Drilling

- Pressure seal ring

- Polishing

5.Pressure seal ring

We use a dedicated embedding press to embed the valve seat as symmetrically as possible into the valve seat,the valve seat provides initial preload force through its own elasticity.Sealing materials generally include:RPTFE、PEEK、PEFE and so on.

production processing

In order to achieve good product quality,every step of production goes through strict procedures.Take ball valve seat for example,The production process is as follows:

- D. Machining

- Heating process

- D. Machining

- Drilling

- Pressure seal ring

- Polishing

6.Polishing

I.D.Machining

Production Processing

In order to achieve good product quality,every step of production goes through strict procedures.Take ball valve seat for example,The production process is as follows:

- D. Machining

- Heating process

- D. Machining

- Drilling

- Pressure seal ring

- Polishing

1.I.D. Machining

In the Rough machining production process,we could detect some situations timely,such as the defects in blank material,or material margin is in sufficient and so on.Then it is convenient for us to repair or scrap raw materials in a timely manner;

Heating process

Production Processing

In order to achieve good product quality,every step of production goes through strict procedures.Take ball valve seat for example,The production process is as follows:

- D. Machining

- Heating process

- D. Machining

- Drilling

- Pressure seal ring

- Polishing

2.heating

In the heating processing,it could improve the mechanical properties of materials,such as hardness, tensile strength, seismic resistance, ductility, and corrosion resistance.And the heating processing consists of three stages:

- heat the material slowly;

- The material is maintained at a specific temperature for a specified period of time;

- Cool the material at room temperature.

O.D.Machining

Production Processing

In order to achieve good product quality,every step of production goes through strict procedures.Take ball valve seat for example,The production process is as follows:

- D. Machining

- Heating process

- D. Machining

- Drilling

- Pressure seal ring

- Polishing

3.O.D. Machining

In the precision machining process,the product will be processed strictly according to the dimensions on the drawing within the allowable tolerance range ,and it will become smoother than before.

Drilling

Production Processing

In order to achieve good product quality,every step of production goes through strict procedures.Take ball valve seat for example,The production process is as follows:

- D. Machining

- Heating process

- D. Machining

- Drilling

- Pressure seal ring

- Polishing

4.Drilling

According to the design requirements of the product, we will drill holes for the valve seat:Spring hole, threaded hole, grease injection hole and so on,different holes will be made by different drilling tools.

Pressure seal ring

Production Processing

In order to achieve good product quality,every step of production goes through strict procedures.Take ball valve seat for example,The production process is as follows:

- D. Machining

- Heating process

- D. Machining

- Drilling

- Pressure seal ring

- Polishing

5.Pressure seal ring

We use a dedicated embedding press to embed the valve seat as symmetrically as possible into the valve seat,the valve seat provides initial preload force through its own elasticity.Sealing materials generally include:RPTFE、PEEK、PEFE and so on.

Polishing

Production Processing

In order to achieve good product quality,every step of production goes through strict procedures.Take ball valve seat for example,The production process is as follows:

- D. Machining

- Heating process

- D. Machining

- Drilling

- Pressure seal ring

- Polishing

6.Polishing