Mission:Ball Valve For A More Reliable & Efficient Flow Control

Vision:One Stop Service for Ball Valves & Ball Valve Components

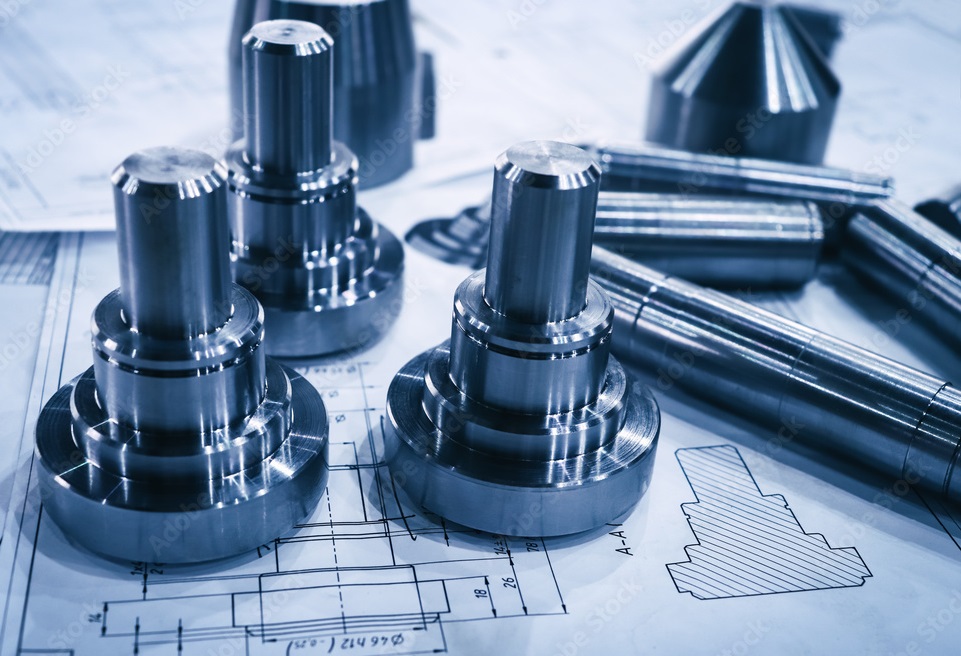

Ballwell is fully dedicated to providing customers with comprehensive solutions for custom-made ball valve and ball valves’ parts & components such ball valve body & bonnet, ball, seat , stem, trunnion, gland, mounting flange, support and etc. including design optimization, quality control, manufacturing, cost control and delivery time guarantees to meet customers’ satisfaction.

Ballwell’s production and service must conform to our stringent standards.

Parameters such as raw material chemical analyses ,tensile test ,heat treatment, tolerance, sphericity, roughness, hardness are tested and recorded during production and special testing (NDT) can be done, on request, during and at the end of manufacturing process, to ensure and guarantee the best quality.

Ballwell’s procedures and quality engineers to guarantee high quality products, on time deliveries, and our continuous improvement have been certified by ISO 9001 accreditation.

Our testing equipments are calibrated by accredited testing laboratories on a regular base.